When replacing a damaged rolling bearing, the bearing can be removed with a screw-type pull-off tool, or pressed out of the inner sleeve or jacket. For the bearing pulling out or pressing out, pay attention to the point of pressure should be uniformly acting on the bearing inner sleeve, the direction of force should be parallel with the axial center; do not allow the bearing sleeve to move out of the transmission shaft in an inclined way, in order to avoid the bearing sleeve strain the transmission shaft working surface.

The choice of mounting method for rolling bearings is determined by the size of the overload between the bearing and the mating shaft. Hand hammering can be used to assemble the smallest size of the excess. When hitting with hand hammer, pay attention to the pressure point should correspond to the alternating hitting, the force should be even; with the shaft to fit the bearing, hit the inner sleeve; with the bearing seat to fit the sleeve, hit the jacket.

If the bearing sleeve and the mating shaft are assembled with a larger size of excess, the bearing can be assembled by the casing method. It is then assembled by hand hammering or using a press according to the size of the surplus. Large bearings or large bearings with oversize size can also be assembled by oil bath heating method, hang the bearings in 80-100 ℃ oil, constant temperature heating for a period of time to remove, and immediately assembled on the shaft.

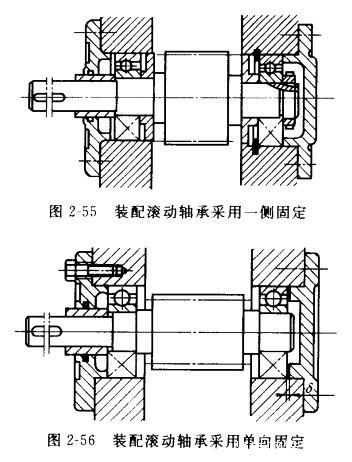

When the rolling bearing is assembled, no matter which mounting form is used, attention should be paid to leave the axial runaway amount when working. The amount of churning is to take into account the bearing work due to the temperature rise and thermal expansion, if the bearing installation does not leave out the axial churning amount, the expansion force on the bearing, it will increase the bearing work load, so that the bearing wears faster. The bearings in Figure 2-55 are assembled so that the right side of the illustrated direction controls the bidirectional movement of the bearings, while the left side leaves a gap between the bearings and the gland. In Figure 2.56, the bearing is mounted on the left side of the bearing jacket, and the right side has some movement clearance, while the inner jacket has no fixed limit on either side.